Milling machine simulator Game Details

Title: Milling machine simulator

Genre: Action, Indie, Simulation

Developer: Igor Frank, Ursa Masnec

Publisher: UI-Games

Release Date: 22 February 2022

Store: Steam

Game Releasers: P2P

About Milling machine simulator Game

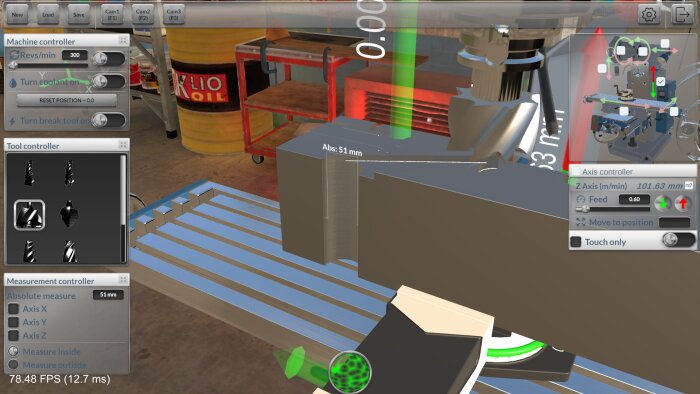

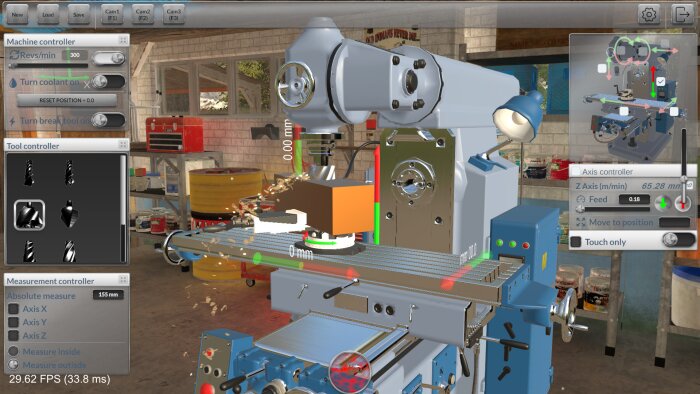

Master the mill! Drill, cut, and prototype in realistic 3D, from free play to challenging career mode.

The digital realm has long been a fertile ground for simulations, offering a safe and accessible space to explore complex processes, develop skills, and indulge in passions without the constraints of the physical world. Among the many fields that have found their virtual counterpart, machining stands out as a particularly compelling and beneficial area for simulation. It allows aspiring machinists to learn the fundamentals, experienced professionals to refine their techniques, and designers to prototype and experiment with new concepts – all within the controlled and cost-effective environment of a computer. The arrival of milling machine simulators represents a significant advancement in this area, offering a meticulously crafted virtual experience that replicates the intricacies and challenges of operating a conventional milling machine.

The allure of a milling machine simulator lies in its ability to bridge the gap between theoretical knowledge and practical application. For individuals new to the world of machining, the simulator provides a gentle introduction to the principles of milling, allowing them to familiarize themselves with the various components of the machine, understand the functions of different cutting tools, and grasp the significance of parameters such as feed rate, spindle speed, and depth of cut. This initial exposure can be invaluable in building a solid foundation of knowledge before venturing into a real-world workshop where mistakes can be costly and potentially dangerous. The simulator acts as a safe and forgiving training ground, encouraging experimentation and allowing users to learn from their errors without fear of damaging equipment or materials.

Experienced machinists, too, can derive considerable benefits from using a milling machine simulator. While they possess the practical skills and intuition honed through years of experience, the simulator offers a unique opportunity to refine their techniques, explore new cutting strategies, and optimize machining processes. It allows them to test different toolpaths, experiment with varying cutting parameters, and analyze the resulting surface finish without the time constraints and material costs associated with traditional machining. This ability to virtually prototype and optimize machining operations can lead to significant improvements in efficiency, accuracy, and overall productivity.

Beyond its educational and training applications, a milling machine simulator can also serve as a powerful tool for design and prototyping. Designers can import their own blueprints into the simulator and use it to evaluate the manufacturability of their designs, identify potential machining challenges, and optimize part geometry for efficient production. This early-stage assessment can prevent costly redesigns later in the development process and ensure that the final product is both functional and easily manufactured. The simulator's ability to replicate the behavior of a real milling machine, including cutting forces, material removal rates, and tool wear, provides a realistic and accurate representation of the machining process, allowing designers to make informed decisions about material selection, tool selection, and machining parameters.

The hallmark of a well-designed milling machine simulator is its ability to create a truly immersive and realistic experience. This requires meticulous attention to detail in replicating the physical characteristics of the milling machine, including its mechanics, controls, and visual appearance. The simulator should accurately model the movement of the machine's axes, the rotation of the spindle, and the interaction between the cutting tool and the workpiece. The user interface should be intuitive and user-friendly, allowing users to easily adjust machining parameters, select cutting tools, and monitor the progress of the machining operation. A realistic soundscape, featuring the hum of the motor, the whir of the spindle, and the sound of metal being cut, can further enhance the immersive experience.

The inclusion of realistic physics and movement is crucial for creating a truly authentic simulation. The simulator should accurately model the forces involved in the machining process, including cutting forces, friction, and vibration. The behavior of the workpiece should also be realistic, with accurate simulation of material removal, surface finish, and the effects of heat generation. Cutting tools should be subject to wear and breakage, forcing users to carefully select appropriate cutting parameters and monitor tool condition. These details contribute to a more realistic and challenging simulation, rewarding careful planning and skillful execution.

A milling machine simulator should offer a variety of modes to cater to different user needs and skill levels. A free milling mode provides a sandbox environment where users can freely experiment with different machining techniques, explore various cutting parameters, and prototype unique products without any predefined objectives or constraints. This mode is ideal for beginners who are just starting to learn the fundamentals of milling, as well as experienced users who want to explore new ideas and push the boundaries of their skills.

In contrast, a career mode presents a structured and challenging experience, guiding users through a series of progressively difficult tasks that test their knowledge and skills. These tasks may involve machining specific parts to precise dimensions, troubleshooting machining problems, or optimizing machining processes for efficiency and cost-effectiveness. The career mode provides a sense of progression and accomplishment, motivating users to improve their skills and master the art of milling. Successful completion of tasks in career mode can unlock new tools, materials, and machining techniques, further enhancing the user's experience and expanding their knowledge.

The ability to customize workpieces is an essential feature of a versatile milling machine simulator. Users should be able to select from a range of materials, each with its own unique machining properties, and to adjust the size and shape of the workpiece to suit their specific needs. This customization allows users to simulate a wide variety of machining scenarios and to experiment with different materials and cutting tools to determine the optimal combination for a particular application.

The implementation of tool breakage is a critical element in enhancing the realism of a milling machine simulator. By simulating the possibility of tool breakage, the simulator forces users to approach the machining process with caution and to carefully select appropriate cutting parameters. It also teaches them to recognize the signs of tool wear and to take preventive measures to avoid tool breakage. This feature adds a degree of challenge and realism to the simulation, making it a more valuable learning experience.

Milling machine simulator Key Features

- * Unleash your inner machinist with the most realistic milling experience ever!

- * Go wild in Free milling mode, crafting your wildest designs with imported blueprints!

- * Test your skills in Career mode, mastering precision and facing intense challenges!

- * Customize workpieces to your exact specifications, choosing materials and sizes!

- * Experience the thrill of realistic physics – even cutting tools can break!

Milling machine simulator Gameplay

Download Links for Milling machine simulator

Download Milling.machine.3D.Build.22031546

Mega

Milling.machine.3D.Build.22031546.zip

1fichier

Milling.machine.3D.Build.22031546.zip

Pixeldrain

Milling.machine.3D.Build.22031546.zip

Mediafire

Milling.machine.3D.Build.22031546.zip

Gofile

Milling.machine.3D.Build.22031546.zip

Ranoz

Milling.machine.3D.Build.22031546.zip

Drop

Milling.machine.3D.Build.22031546.zip

Bowfile

Milling.machine.3D.Build.22031546.zip

Frdl

Milling.machine.3D.Build.22031546.zip

Wdfiles

Milling.machine.3D.Build.22031546.zip

Chomikuj

Milling.machine.3D.Build.22031546.zip

Vikingfile

Milling.machine.3D.Build.22031546.zip

Down mdiaload

Milling.machine.3D.Build.22031546.zip

Hexload

Milling.machine.3D.Build.22031546.zip

1cloudfile

Milling.machine.3D.Build.22031546.zip

Usersdrive

Milling.machine.3D.Build.22031546.zip

Megaup

Milling.machine.3D.Build.22031546.zip

Clicknupload

Milling.machine.3D.Build.22031546.zip

Dailyuploads

Milling.machine.3D.Build.22031546.zip

Ddownload

Milling.machine.3D.Build.22031546.zip

Rapidgator

Milling.machine.3D.Build.22031546.zip

Nitroflare

Milling.machine.3D.Build.22031546.zip

Turbobit

Milling.machine.3D.Build.22031546.zip

System Requirements for Milling machine simulator

To effectively run the milling machine simulator, users will need a computer running Windows 10 or 11. For a minimally acceptable experience, the system should have an Intel i3 processor, 4 GB of RAM, and an AMD Radeon (TM) Graphics card with 512MB of VRAM, along with 2 GB of available storage space. However, for a more optimal and smoother experience, it is recommended to use a machine with an Intel i5 processor, 8 GB of RAM, an NVIDIA GeForce GTX 1060 or equivalent graphics card, and 4 GB of available storage space.

Minimum:- OS: Windows 10, 11

- Processor: i3

- Memory: 8 GB RAM

- Graphics: AMD Radeon (TM) Graphics 512MB

- Storage: 5 GB available space

- OS: Windows 10, 11

- Processor: i5

- Memory: 16 GB RAM

- Graphics: NVIDIA GeForce GTX 1060 or equivalent

- Storage: 10 GB available space

How to Download Milling machine simulator PC Game

1. Extract Release

2. Launch The Game

3. Play!